- Strona główna

- Druk wielkoformatowy

Druk wielkoformatowy

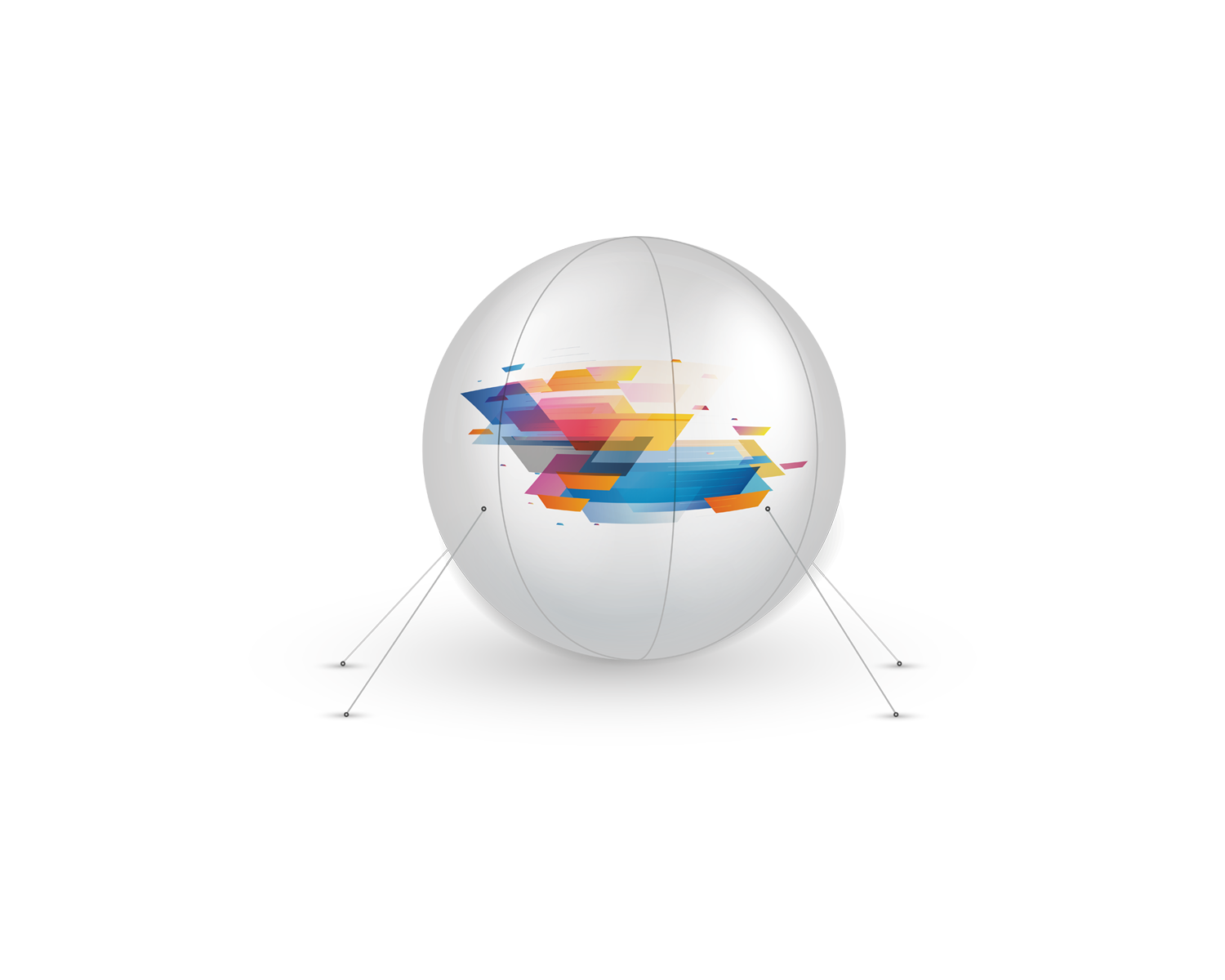

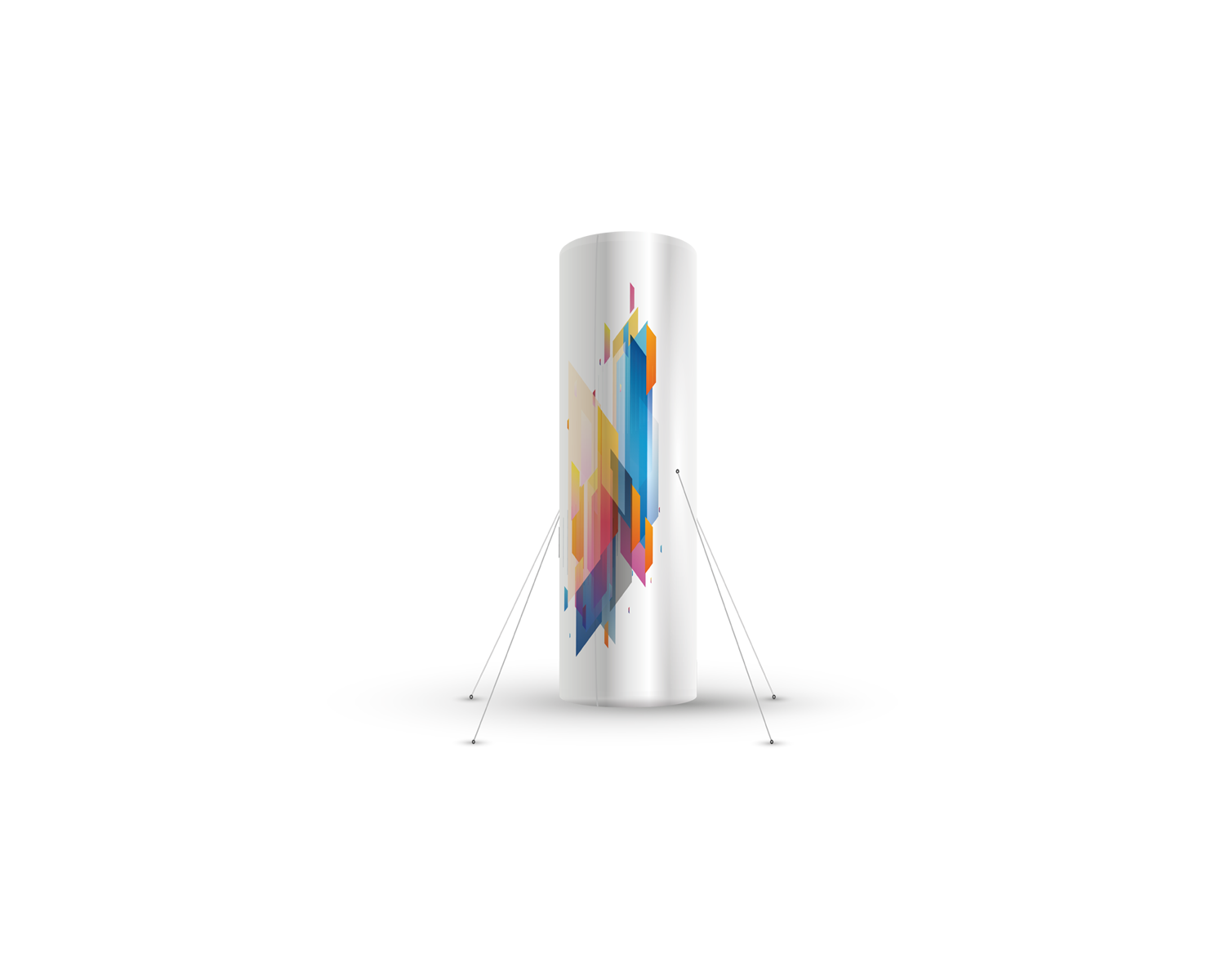

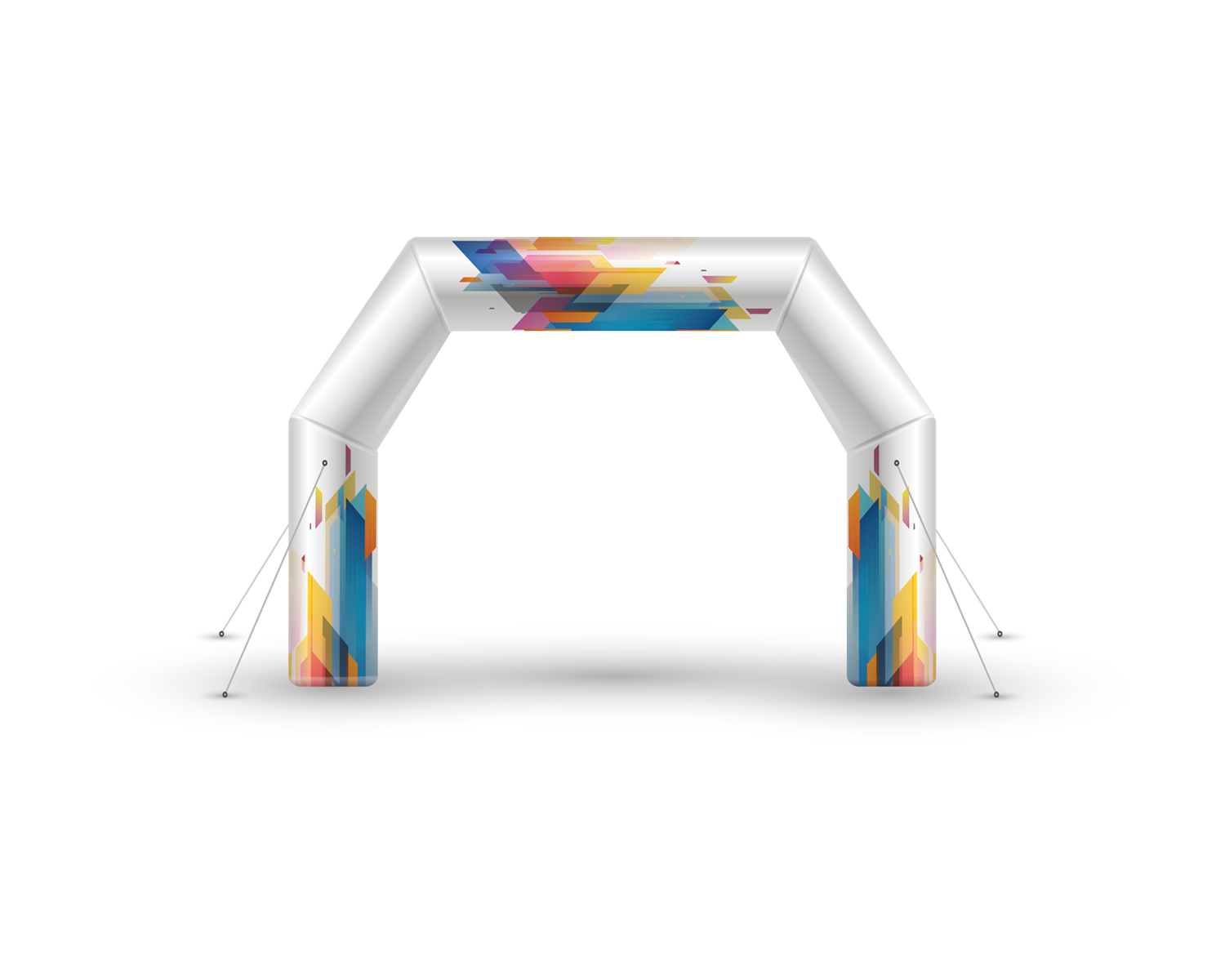

Najwyższa jakość druku, szybka realizacja i trwałość zamawianych u nas materiałów to wynik pasji i wieloletniego doświadczenia w branży. Jesteśmy na rynku już 25 lat, a naszą misją jest połączenie tradycji z nowoczesnymi trendami w reklamie. Wykonujemy druk wielkoformatowy w technologii solwentowej, sublimacyjnej i UV, tak aby powstała w ten sposób reklama, była najlepszą wizytówką Twojej firmy i zachowała swoje walory przez wiele lat.

W realizacji Twojego pomysłu wykorzystamy nowoczesną technologię i najnowszej generacji park maszyn. Druk wielkoformatowy wykonany przez Grupę Luxpol jest trwały i efektowny.

Informacje o produkcie

Najwyższa jakość i nasycenie druku

Szybki czas realizacji

Studio graficzne

Drukarnia solventowa

Druk solwentowy sprawdzi się na reklamach zewnętrznych, takich jak np. bannery, billboardy, plakaty, siatki wielkopowierzchniowe, folie, roll up’y i będzie wytrzymały na zmieniające się warunki atmosferyczne, czyli może wisieć w miejscach bardzo nasłonecznionych, jak i zostać poddany próbie wiatru, deszczu i śniegu.

Czym się zajmujemy?

Druk solwentowy różni się ty od tradycyjnych metod, że zamiast atramentów na bazie wodnej, stosowane są pigmentowe atramenty na bazie rozpuszczalników. W technologii solwentowej wykonujemy:

- Baner Frontlit (laminat).

- Baner Frontlit powlekany.

- Baner Blockout.

- Siatka laminowana B1.

- Folia monomeryczna.

- Folia przeźroczysta.

- Folia backlit.

- Folia wylewana (na samochody)

- Folia polimerowa.

- Folia OWV (okienna).

- Polycanvas (imitacja płótna).

- Papier blue back side (billboardowy).

Jeżeli nie masz jeszcze gotowego projektu, pomożemy Ci go przygotować, tak aby Twoja reklama wyróżniała się spośród konkurencji. Wystarczy, że skorzystasz z naszego programu partnerskiego, a wtedy projekt wykonamy za darmo. Reklama w rozmiarze XXL daje naprawdę duże pole do popisu. Pomożemy wykorzystać Ci tę możliwość jak najlepiej!

Gdzie nas znajdziesz?

Drukarnia Grupy Luxpol mieści się w Tychach, ale swoją działalnością obejmujemy całą Polskę i kraje europejskie. Można się z nami skontaktować elektronicznie lub telefonicznie i uzgodnić wszystkie szczegóły reklamy. Nasi doradcy handlowi są do Państwa dyspozycji, służą swoją wiedzą i doświadczeniem, tak aby zamówiony u nas druk wielkoformatowy spełnił wszystkie oczekiwania Klienta.

Przykładowe realizacje naszych usług widoczne są w galerii na stronie internetowej. Wśród naszych zleceniobiorców są zarówno prywatne firmy jak i instytucje publiczne, specjalizujemy się zatem w projektach odważnych, nowatorskich, ale również konwencjonalnych i tradycyjnych, tak aby wybrana kampania reklamowa najlepiej trafiała do jej odbiorców.